A recent Facebook post about a collision involving a Tesla Cybertruck showed the Cybertruck unscathed and the other vehicle demolished, while the Cybertruck driver was injured and the vehicle passengers were unharmed. The post blamed this on a lack of crumple zones in the Cybertruck, and we ended up giving a brief explanation of crumple zones to one of the Commenters. This brought up two questions for us… one, do our readers know what (and how important!) crumple zones are, and two, does the Cybertruck REALLY not have crumple zones? Here’s our best attempt at answers…

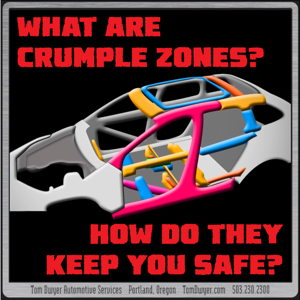

What are crumple zones and how do they work?

Before the 1950’s, crumple zones were a fantasy because cars were built to survive accidents, period. But in 1937, Bela Barenyl patented a way to build compartments around the cars’ engine and trunk to bend and crumple so that the force of an accident could be reduced and directed around the passengers instead of through them. Turns out his ideas made sense, and Mercedes-Benz began producing cars with partial crumple zones in 1953.

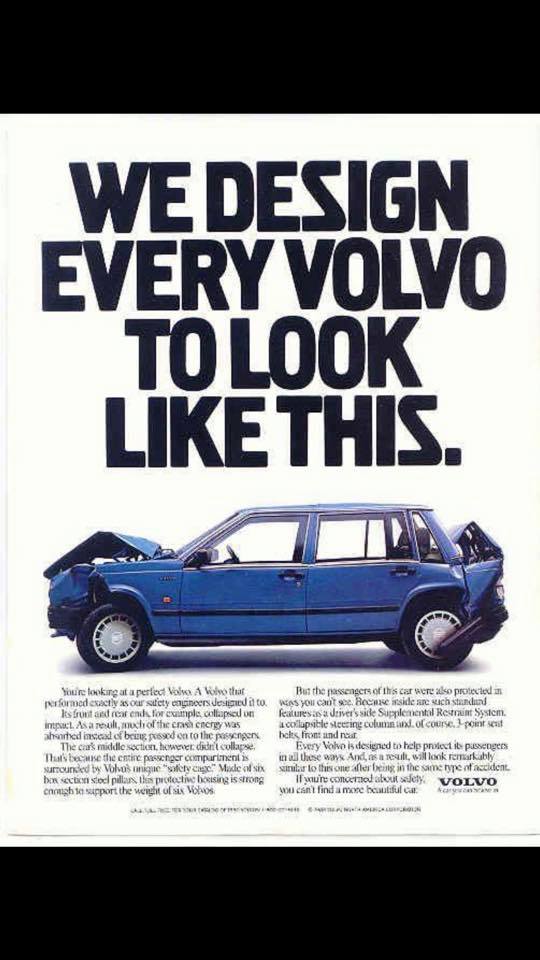

When you’re in an accident THE VEHICLE goes from driving speed (say 30 mph) to 0 mph in about .1 seconds, creating an impact force (deceleration). YOU keep going until you’re stopped by a steering wheel, dashboard, windshield, or (preferably) by a seat belt and airbag, which you’ll hit with the impact force of the accident. Crumple zones work by 1) reducing the impact force on the passenger compartment and 2) directing forces and objects around the passenger compartment.

The force of the impact depends on the F=ma equation from physics, which is critically dependent on the time it takes to decelerate. If you can stretch the impact time from .1 seconds to .2 seconds, you’ve halved the impact force. Stretch it to .4 seconds and the force is halved again. In rigid vehicles the structure stays intact so the deceleration is immediate, but using materials of varying strengths in the front and back means parts fail in sequence. This stretches the deceleration time out for a few possibly lifesaving microseconds. More rigid components around the passenger compartment itself keep it from crushing in on the passengers.

To direct forces around the passengers, individual structural members collapse in a way that pushes components and forces in new directions. The best example is your engine, which in old style vehicles became a battering ram blowing through your family at 30 mph. The frames of modern vehicles collapse to direct the engine downward and under the compartment. Your engine won’t survive (if it ever would have anyway) but your family will be much happier.

You can’t put Humpty Dumpty together again

One important thing about crumple zones is they’re one-use only. Once a component has been bent its structural strength is gone, and it CANNOT be straightened and reused. Our old Service Advisor Steve had the best illustration… it’s hard to crush an aluminum can once, but if you restraighten it then it’s easy to crush it a second time. Crumple zones depend on materials bending in PRECISELY the right way at PRECISELY the right time, so any deviation from the original design specs can be fatal. This is just one of the reasons we recommend you NEVER BUY A SALVAGE TITLE VEHICLE… if a frame was straightened after one accident, it almost certainly won’t collapse correctly in the next one.

The best illustration of crumple zones ever

In January 2015 Oregon was facing another spell of freezing weather, and 26 vehicles piled up on the ice outside Baker City. One vehicle in this mess made the national news… Kaleb Whitby’s pickup truck was utterly demolished, squashed between two semi trucks. Kaleb walked away with just scratches though, because his vehicle crumpled around him to form a small but livable chamber that fit as tight as his clothes. Click here to read the whole story of the accident from CNN, and click here to get an incredible up-close look at Kaleb’s vehicle which now resides in a Baker City tow yard.

So what about the Cybertruck?

This whole thing came up because of that Facebook post about a Cybertruck not having crumple zones. Is that true? Knowing how trustworthy the InterTubes are, we did our own research and found… well, nothing conclusive. There was nothing that said “Yes! Of course!”, but the designers seem to have something similar in mind. According to Tesla, “Cybertruck’s front underbody casting is designed to break into small pieces. This helps reduce occupant impact by absorbing & dispensing energy.” How well this will work given the stiffness of Cybertruck’s stainless steel remains to be seen. Tesla has done internal testing and NHTSA will be doing their own independent testing soon, but there’s nothing definitive so far.

Digging Deeper-

How Crumple Zones Work, Ed Grabianowski on HowStuffWorks, Apr 2021

Crumple Zone Physics Demonstrate How Less Stiff Plastic Materials Can Help Prevent Injury and Save Lives, Automotive Plastics

Crumple Zone Explained (video), Nonda Auto DIY Center, May 2023

Why You Want Your Car To Crumple, Ashlyne on Road Sense Australia, Aug 2022

Driver pinned between 2 semi trucks tells of terrifying crash, Sutton and Yan on CNN, Jan 2015

I-84 crash: Kaleb Whitby’s demolished truck sits in a Baker City tow yard, The Oregonian, 2016

Cybertruck Crash Test is HORRIFYING, Here’s Why, AI DRIVR on Youtube

Here’s How The Tesla Cybertruck Holds Up In A Crash Test [Update], Suvrat Kothari on InsideEVs, Dec 2023

If the Cybertruck is deadly for pedestrians, it’s because all large trucks are, Andrew Hawkins on The Verge, Dec 2023

Tesla explains novel Cybertruck front crumple zone design, Simon Alvarez on Teslarati.com, Dec 2023

Cars are designed to crumple, Sydney Morning Herald, 2016