It’s a tiny detail, but it’s critical to your safety

Even if you’re “not a car person” you still know wheels must stay attached to a vehicle for safe and proper function. You probably also know they’re secured with fasteners commonly called “lug nuts”, but did you know there are right and wrong ways to install these seemingly-simple nuts? Too tight can be just as bad as too loose, and tightening them carelessly can lead to wheel damage or stud or nut failure. Here’s a look at how the little detail of proper nut tightening matters, what happens if it’s ignored, and how the unique procedures we’ve established ensure this vital detail is taken care of reliably for every client…

The nuts and bolts of nuts and bolts

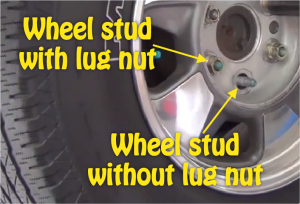

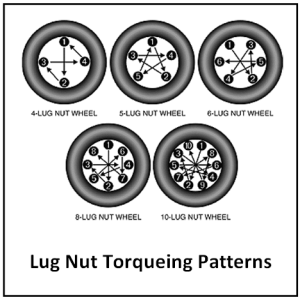

Wheels are mount with (often) 5 threaded bolts called “studs” or “lugs”, each with its own specially designed lug nut. Lug nuts perform much as any other nut, but they must be tightened sequentially and tightened to a very specific tension to work reliably. Carelessly blasting them into place with air tools can be problematic! The wheel lugs, not matter how many, must be installed and gradually and sequentially tightened up to the point the final “tightness” or torque is applied with a torque wrench to the vehicle manufacture’s exact specification… too tight can be just as bad as too loose.

“Torque” is the amount of twisting force used to tighten a nut. It’s commonly measured in foot-pounds (ft-lbs), and the proper torque for lug nuts varies from as low as 60 ft-lbs to over 120 ft-lbs. Whether the wheels are cast, stamped, machined; made from aluminum. magnesium or steel, the diameter and metallurgy of the wheel stud itself, vehicle weight, the number of wheel nuts (4, 5, 6 even 8 or even more for larger vehicles), and the design of the lug nut itself all play a part in determining the ideal torque specification for every vehicle.

The torque specification is designed to ensure the wheel fasteners will be reliable over repeated cycles of removal and reinstallation and not fail or cause wheel or other damage. Although metal seems rigid it’s actually slightly springy and pliable, so when a nut is tightened the bolt actually stretches. This is taken into account in the design of the nut and bolt, and in a properly tightened nut the slight pressure of the bolt trying to return to its normal shape actually helps hold the nut securely in place. It may be tempting to tighten a nut as hard as possible but over-tightening can be almost as bad as under-tightening. Lug nuts that are over tightened can stretch the bolt past its elastic limit so it can’t spring back to normal shape, leaving the nut without the pressure it needs to work correctly.

What can possibly go wrong?

Failure to observe proper torque specifications or procedures can cause problems, none of which are pleasant or inexpensive.

- The obvious worst possibility is that when wheel lug nuts are too loose they can back off and can cause the wheel to separate from the vehicle… very bad!

- Over-tightened wheel lug nuts can damage the wheel, and actually stretch the wheel studs, making them weak and subject to failure. If one stud fails as a result of over-torque the others possibly experienced similar treatment and may be damaged as well. One failed lug will not cause the wheel to come off, but now you have one broken wheel stud with the others taking up a load higher than they were designed for. Over-tightened lug nuts or failure to use gradual sequential tensioning can also damage the wheel and cause warped brake rotors. All of these can lead to an unneeded car repair bill; bad!

- Lug nuts that are too tight can be really hard to remove without air tools. If you have a flat and the last person to install the wheels blasted them on with air tools, good luck getting the lug nuts off with the cheesy lug wrench supplied in the vehicle’s spare tire kit; not good!

How do we prevent these problems?

Knowing the proper nut torque is one thing, but achieving it is another and achieving it consistently on every vehicle we service is something else again. We’ve done it by setting a rigorous procedure that honors the fine details necessary for proper installation, and then building in layers of safety protocols and failsafes so our Technicians always know the procedure has been followed. We know every wheel we remove is reinstalled and hand-torqued to the vehicle manufacturer’s specification.

Our torqueing procedure

Each nut must be tightened in the proper order in steps to get close to but less than the proper torque, and then finished with a torque wrench (still in the proper order) to achieve the precise final tension. It’s important that this final step of tensioning is applied with a torque wrench and not just checked with a torque wrench! If that sounds like a small detail, it’s not. A lug nut blasted into place by a brute with an air gun on its highest setting will definitely be way over the designated torque, but when “checked with a torque wrench” it will appear to be fine.

Each nut must be tightened in the proper order in steps to get close to but less than the proper torque, and then finished with a torque wrench (still in the proper order) to achieve the precise final tension. It’s important that this final step of tensioning is applied with a torque wrench and not just checked with a torque wrench! If that sounds like a small detail, it’s not. A lug nut blasted into place by a brute with an air gun on its highest setting will definitely be way over the designated torque, but when “checked with a torque wrench” it will appear to be fine.

The failsafes

Prior to torqueing– It’s impossible to tell visually if a nut in its final position is properly torqued, so we never get it close enough to have any doubt. When our Technicians are working with wheels they often use a lug nut to hold the wheel in place, but they’ll only put it on a few threads (until the final steps) so it’s visually obvious that the nut has not been tightened OR torqued.

After torqueing– After ALL the nuts on a single wheel have been torqued to the correct spec and in the correct pattern, we make a small chalk mark next to the air stem of the tire to indicate that the lug nuts on that wheel are torqued and safe. This process is performed one wheel at a time. This is a clear indicator to the Technician working on the vehicle that those wheel lug nuts are torqued… there’s no “wait, did I do that one?” type of doubt involved. It also serves as point of confirmation in our Post Service checkout, where the staff knows to look for chalk marks on every tire that’s been removed and reinstalled for service.

One other small detail about that chalk mark… we change chalk colors each year so there is no confusion if a mark is new or old. In 2023 we will be using RED chalk to mark your tires. So now when you see that little RED mark on your tires after service you know why it’s there and you can feel good about all the thinking that goes into just that one little mark.

Our final failsafe is possibly our best… the personal integrity and responsibility of our Technicians. The issue of wheel torque is so important it’s one of the few technical issues in our Policy Manual for new Technicians. It states that “All wheels will be properly hand-torqued to the vehicle’s specifications”, and “Tires will be clearly marked on the inboard sidewall and a small but visible dot adjacent to the valve stem on the outboard side of a torqued wheel, using a tire crayon of the currently assigned color”, and that violating that standard is grounds for termination. All our people know how seriously we take this as a company, so they know to take it seriously themselves.

What’s been the result?

There are lots of serious problems that can arise from your vehicle, but things that make it catch fire, make its wheels fall off, or make it lose brake hydraulics are things we take particularly seriously. In the first 18 years of operation we had two episodes of a loose wheel causing problems (fortunately none caused accidents) but two is too many. Anytime we have a problem from operations we learn and formulate a response or change to policy to prevent a recurrence and wheel torque was no exception. We are serious about proper wheel lug nut etiquette and we had two episodes in the 22 years since. As far as we know it’s a level of detail and commitment that no other shops approach, but it’s typical of the fanatic commitment we have our clients’ safety and driving confidence.

######################################

Thinking about tires?

If you’re interested in the proper tightness of wheel nuts it may be because you’re thinking about new tires for your vehicle. If that’s the case, then you’ll want to know Tom Dwyer Automotive Services carries tires in all sizes and specifications from the most common to the most exotic, and we’ll gladly help you with your tire needs. Let us start now by offering some of our tire advice from past issues of our newsletter, and you can always give our non-commissioned Service Advisors a call for their answers to any specific questions you might have.

Where The Rubber Meets The Road- The Basics Of Tire Selection And Purchase

Does Baby Need A New Pair Of Shoes? How To Pick The Right Tires For Your Vehicle

Will Polyurethane Replace Rubber For Tires?

Why Are Tires Black? When Should I Replace My Tires?